Working with ABS plastic : r/moldmaking - abs injection

Author:gly Date: 2024-10-15

Negri Bossi provide special applications for thermoset injection molding. This solution includes all the equipment required for reliable and optimal production of high-quality molded parts.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The process for injection molding thermoplastic elastomers (TPEs) requires precise control of the molding conditions, including temperature, pressure, and cooling time, to ensure consistent and high-quality parts. The process involves the following steps:

Injection molding with thermoplastic elastomers (TPEs) is a manufacturing process where TPE material is melted and injected into a mold cavity to form a specific shape. TPEs are a type of polymer that has both plastic and rubber-like properties, making them suitable for applications that require both flexibility and strength. The resulting molded part can have a wide range of physical and mechanical properties, depending on the specific TPE material used and the molding conditions. Injection molding with TPEs is commonly used by a variety of industries, including automotive, consumer goods, and medical devices.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

By following these guidelines and working with experienced and knowledgeable professionals, it is possible to achieve success with injection molding of TPEs and to produce high-quality, consistent parts.

Access a wide breadth of capabilities through our highly vetted network.

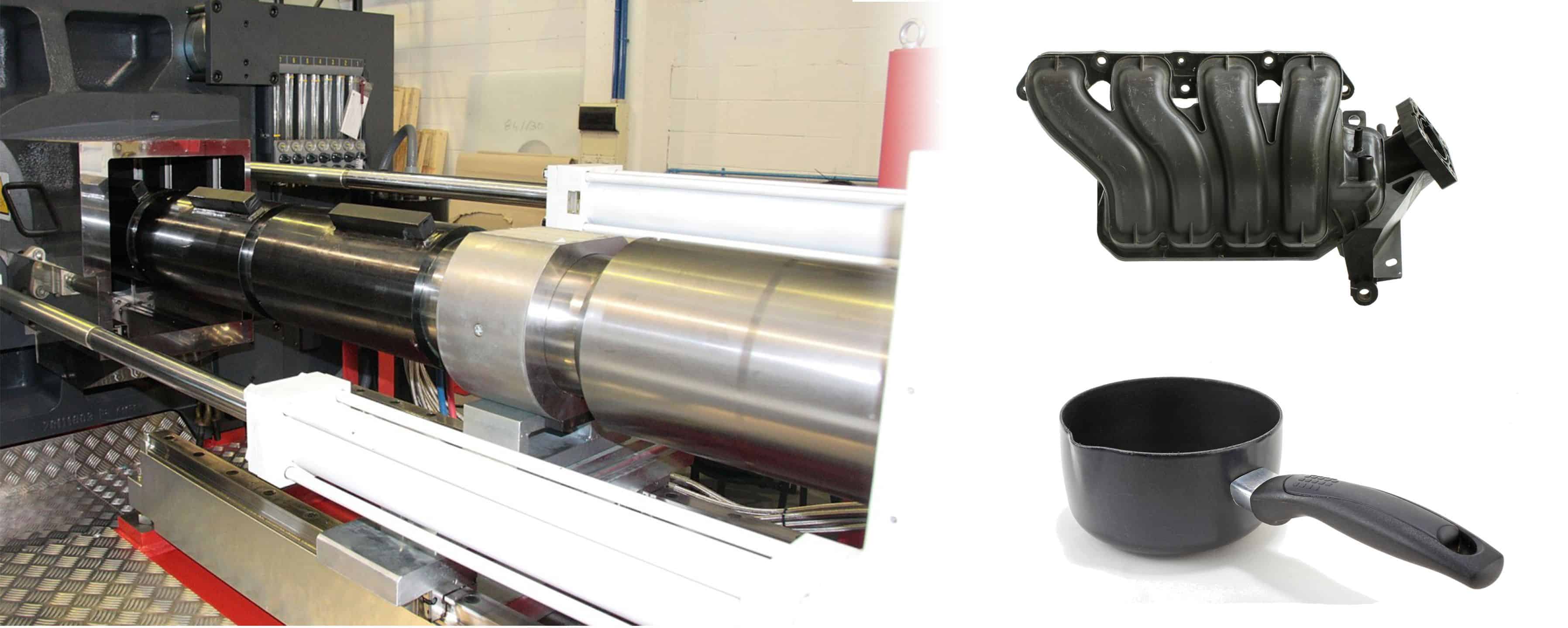

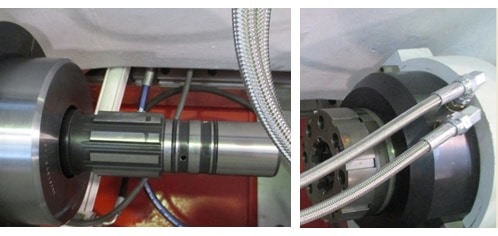

Figure 1. Injection Unit Figure 2 & 3. Thermoregulated screw and distribution Figure 4-7. Thermoregulated barrel and distribution

Thermoset plastics are generally stronger than thermoplastic materials due to the three-dimensional network of bonds (crosslinking), and are also better suited to high-temperature applications. They have high mechanical strength and rigidity and are frequently used to replace metals, reducing the weight by as much as 75%. Thermoset materials are often used in vehicle engine compartments, oil pump and thermostat housings, water inlets & outlets and impellers. Brake linings and disk brake pads can also be manufactured in thermoset plastic.

Pro-tip: If you want to learn more about designing for injection molding, check out our downloadable Injection Molding Design Guide.

TPEs are a relatively common injection molding plastic, but a good plan and skilled production partner is still critical to avoid the added costs and risks that come with inadequate drying or improper processing methods. Fictiv has the global manufacturing network and production experts you need to get quality TPE parts. As your operating system for custom manufacturing, Fictiv has the skills and knowhow to support you from part design through prototyping and production.

Our trained employees ensure your parts will be delivered on time and to spec.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Thermoplastic elastomers (TPEs) have a combination of rubber-like and plastic-like properties, which result in several specific material properties:

The specific properties of TPEs can vary depending on the formulation and the specific application, so it’s important to choose the right TPE material for the specific requirements of the part.

Create high quality custom mechanicals with precision and accuracy.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Designing for injection molding of thermoplastic elastomers (TPEs) involves several guidelines that can ensure proper and consistent molding, including:

Accelerate development with instant quotes, expert DFM, and automated production updates.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Create your free Fictiv account and request an injection molding quote today — we mold complex parts at ridiculous speeds!

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Success with injection molding of thermoplastic elastomers (TPEs) requires careful planning and attention to detail, including:

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly