What is the Cost of Plastic Injection Molding? - custom injection molding cost

Author:gly Date: 2024-10-15

High and Low Molecular Weight PC: High molecular weight PC has longer chain lengths, typically showing higher strength, better heat resistance, and superior mechanical properties. It’s suitable for high-performance applications like bulletproof materials and high-end mechanical parts. Conversely, low molecular weight PC, with shorter chain lengths, is easier to process and mold but usually means lower mechanical strength and heat resistance. This type of PC is more suitable for general consumer products and non-heavy-duty applications.

Glass Fiber Reinforced PC: Reinforcing PC with glass fibers enhances its mechanical strength and dimensional stability, making it more suitable for applications requiring high strength and rigidity.

UV Resistant PC: By adding UV stabilizers, the weather resistance of PC for outdoor use is enhanced, reducing discoloration and performance degradation due to prolonged UV exposure.

These parameters should be adjusted and optimized according to actual machine conditions, material characteristics, and product design requirements. Correct injection molding parameters are essential for ensuring product quality and production efficiency.

These applications demonstrate the widespread use of PC in modern industry and everyday life. Its features, such as high transparency, strength, and flame retardancy, play an important role in many fields.

Polycarbonate (PC) plays a crucial role in various injection molding products due to its unique characteristics and is widely used in the following areas:

Let’s quickly understand the various types of Polycarbonate (PC) and the nature of modified PC. Modified PC refers to the materials obtained by adding different reinforcing materials or additives to the base PC resin to improve or enhance its original properties. Common types of modified PC include:

These modified PC materials, with their unique combination of properties, find widespread applications in various industrial fields. Through modification, the application range of PC has been greatly expanded, meeting more stringent or specific performance requirements.

Electronic Device Casings: Including casings for computers and headphones, the application of PC material provides a solution that is lightweight, durable, and aesthetically pleasing.

Casings for Electrical Products: PC is also widely used in manufacturing casings for electrical products, such as electric meter housings. The choice of PC is mainly due to its flame-retardant properties, weather resistance, and high strength and toughness, ensuring the safety and durability of electrical products.

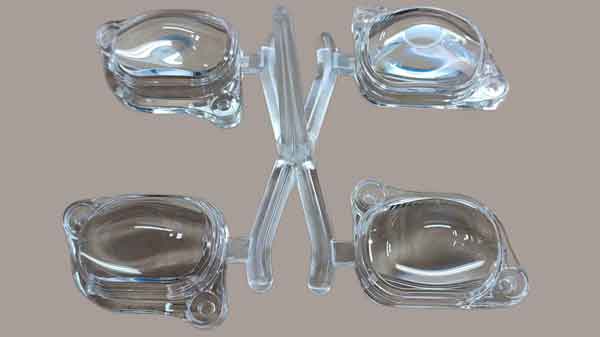

Transparent Casings and Goggles: PC’s high transparency and strength make it ideal for manufacturing various transparent casings and goggles.

Understanding the right parameters for injection molding of PC is crucial for optimal product quality. Here’s an overview:

AIC mould is located in Huangyan Beicheng Industrial Park, Taizhou City, Zhejiang Province, China. It is adjacent to the Yangtze River Delta Economic Zone and is connected to Taizhou Bay Container Terminal, Luqiao Airport and Hangzhou-Ningbo Expressway. The traffic is very convenient and fast. The company has a beautiful environment and strong technical force. It has many years of experience in mold development and design. Mainly engaged in the development and production of plastic molds for daily necessities, logistics products, etc., mold products cover a variety of large and medium-sized injection molds.

Injection pallet molds usually produce only one product at a time, and different structural forms of the pallet mould can produce pallet of different shapes. This article mainly introduces plastic injection pallets, which can be used to process and store goods in terminals, freight yards, warehouses, workshops, shopping malls, supermarkets, etc. The tray consists of a base and a flat surface. The fork of the forklift can be operated in both directions for easy operation. The mold has a great influence on the production of the pallet, and the carrying capacity and defects of the pallet are directly related to the mold.

PC/ASA Alloy: Alloying with ASA (Acrylate-Styrene-Acrylonitrile) improves weatherability and UV resistance, suitable for applications that are exposed outdoors for long periods.

Flame Retardant PC: The addition of flame retardants improves PC’s flame retardant properties. Unmodified, PC has a V2 flame retardant rating, insufficient for many products. With added flame retardants, it can reach a V0 rating. Flame retardants can be halogenated or non-halogenated.

The injection molding pallet mold is an indispensable device in the injection pallet production line, and is mainly composed of an upper and lower mold body and a demolding injection mechanism. In the injection molding process, the upper mold and the lower mold are combined to form a closed cavity, and the plastic injection molded into the cavity is injection molded, and the entire injection molding tray is completed after being released from the injector.

Transparent PC: Although PC is inherently transparent, specific modifications can further enhance its transparency and optical properties, suitable for optical products and decorative items that require high transparency.

In recent years, it has been devoted to the research and development of BMC/SMC molding dies for various types of bumpers. It is currently one of the few manufacturers in China that has developed BMC/SMC molding dies. Since its inception, AIC Mould Factory has established an enterprise policy of “service first, quality one”. The company provides customers with high quality services with loyal and effective work and reasonable prices. We sincerely welcome new and old customers at home and abroad to inspect and guide! Create a brilliant career!

PC/ABS Alloy: Mixing PC with ABS (Acrylonitrile Butadiene Styrene) combines the high strength and heat resistance of PC with the ease of processing and surface smoothness of ABS, along with stress crack resistance. This is widely used in automotive parts, electronic device casings, and more.

Safety Helmets: The high impact resistance of PC makes it an ideal material for manufacturing safety helmets, which are extensively used in construction, sports, and other fields requiring head protection.

Optical Discs: Optical discs, such as CDs and DVDs, are typically made of PC material, benefiting from its excellent optical properties and processability.

PC/PBT or PC/PET Alloy: By blending with PBT (Polybutylene Terephthalate) or PET (Polyethylene Terephthalate), chemical resistance and impact resistance are enhanced, often used for products requiring chemical corrosion resistance and high impact strength.

Carbon Fiber Reinforced PC: Incorporating carbon fibers improves the material’s strength and thermal stability, suitable for lightweight and high-performance applications in aerospace and automotive industries.

Our Advantage of: 1.Customized mould making according to customer's requirements 2.Experienced group for part&Mould design 3.On-time delivery 4.Advanced Equipment 5.One-year-warranty for each mold

The company introduces many international and advanced equipments at home and abroad, including complete CAD/CAE/CAM system, computer three-dimensional measuring instrument, CNC computer controlled electric discharge machining center. The current production, sales and specifications are at the forefront of the industry. According to the requirements of users, the company designs and manufactures mould products with various needs.

Polycarbonate (PC) is an amorphous thermoplastic material, a high polymer containing carbonate groups (-O-C(=O)-O-) in its molecular chain. It is synthesized through a polymerization reaction involving Bisphenol A (BPA) and Phosgene (COCl2). Known as a high-performance thermoplastic, PC is widely used for its outstanding transparency, heat resistance, and impact resistance.

AIC mould into plastic inection moulding industry more then 10 years. We insist to choose suitable mould machining, use high quaility moluld spare part, strict to check every step. High quality mould, suitable price is our aim.

In conclusion, mastering polycarbonate in injection molding opens up a realm of high-performance applications due to its unique properties. By understanding the right techniques, parameters, and modifications, manufacturers and designers can harness the full potential of PC, ensuring durable, high-quality, and versatile products in a wide range of industries.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly