What is Thermoplastic Injection Molding? - thermoplastic injection

Author:gly Date: 2024-10-15

That being true then there are a few really talented people out there making mold for us. Are we not lucky that they fish instead of some other sport. Got to love that. Frank

I also put the plastic I trim from baits in the second container and remelt when I start to run low on plastic in my cup. I only shoot one bait style at a time, but if you have multiple molds and want the same color/salt content, ect...you could set up a production line without having to clean until your injector empties. get the biggest injector they have. Better to have it and not need it than need it and not have it.

all that detail is in the person programming the cutter paths. 2 people can take the same CAD files and create different looking baits based on what cutters they use and the paths they choose.

I will also add that I was able to get a prototype mold PRIOR to getting the final molds cut.... Sweet deal as I could make adjustments if needed and then get the final molds. The prototype was dead on so it was all incredibly fast.

If you put the plastic that comes off the exterior and the remaining cooled interior plastic back in the pyrex cup, you'll quickly be sucking up partially solidified plastisol and it'll clog the noozle.

I don't have any experience with Bears equipment, but I have no doubt that he makes a super product that can be trusted for years to come. I don't think you could go wrong with either.

I have the Bears two color injectors,and I have tried my best to keep mine from coming out,I push it up against the pyrex cup on a angle and have done everything I now to do and mine still come out.Iv'e considered making a stand with holes the size of the injector tips,so I could push against them to empty my injectors in the cups.I really like every thing else that Iv'e bought fron Bears,and He is a great guy to deal with.I just wish the injectors did not have a hair trigger on them popping out.Iv'e used his single injector for some time now and have no problem uing them,but two color has been some thing else.I read this site most every day and read that a lot of people prefer the no pin injectors but I have tried and tried to get a handle on using the two color injectors and still have not got it done.

all that detail is in the person programming the cutter paths. 2 people can take the same CAD files and create different looking baits based on what cutters they use and the paths they choose.

I have had the Basstackles Twinjector since before it had pins to hold the tips on. Now that was a pain to eject the plastic from two at the same time, one always came out. I posted the fix in an email to him and he imediatly saw the advantage of this simple fix. From then on he has incorperated it into all of his injectors. It takes no time at all to get use to the tip, with the slight turn it comes off and a slight turn back and it will never fall off. Yes his two color system has more parts but the convinience of filling two colors at the same time saves alot of greif. Kevin does listen to his customers and is willing to make changes to his products, for us the end user. You can see by the molds that he is producing he is listening. That is good for us all. Frank

My son does some parts designing for his company for there cncs and he sees the molds and says his programmer in no way shape or form can even come close to what is in those molds. You being in that part might know is that a program or is it the person programming those details? As many people already know Kevin can produce a mold from an email in just a few hours. How I dont know but he has done it for me and many others that have told me. Bears mold maker has that talent also just take a look at his hollow swim and you can see it. Getting X Y and Z to flow like that is a great thing for us to make some of the best baits out there. Like I said before this is great for all of us. Frank

Most compatable, Easy to use, And clean, Etc. Is there anything I will need with the injector like an adaptor for the Del's mold new to this stuff haha

all that detail is in the person programming the cutter paths. 2 people can take the same CAD files and create different looking baits based on what cutters they use and the paths they choose.

Most compatable, Easy to use, And clean, Etc. Is there anything I will need with the injector like an adaptor for the Del's mold new to this stuff haha

The clean up is super easy. Once the bait is injected, squirt the rest of the plastic back in the pyrex cup, roll off the excess on the exterior into a 2nd container, twist off the tip of the injector, and push the rod through to retreive the remaining plastic on the interior. Put that in the 2nd container, and reapply the tip. Your ready to fill the injector again in less 10 seconds.

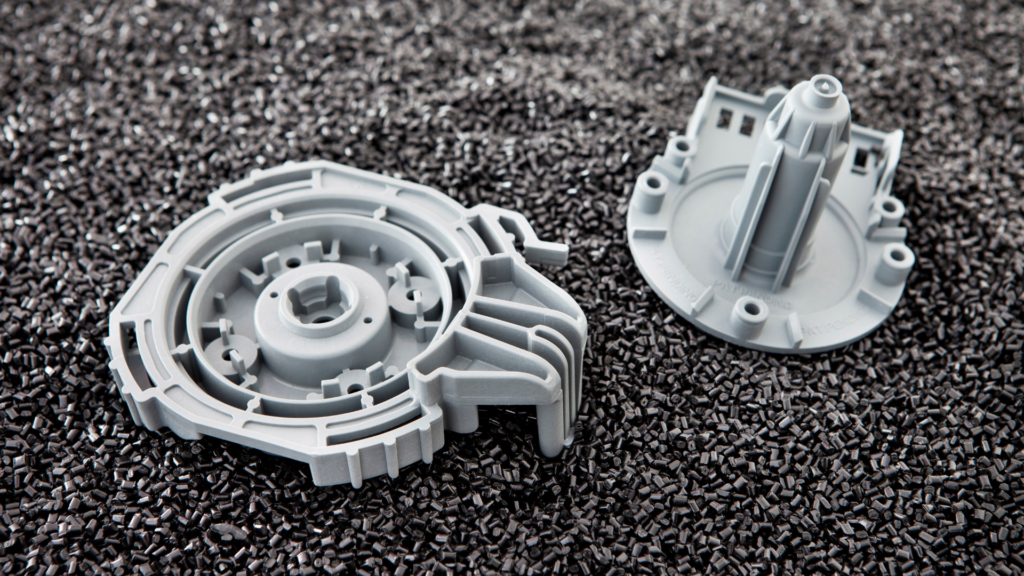

The team at UPTIVE has accelerated this process for faster tooling turnaround with multiple options, including rapid injection tooling, bridge tooling, and production tooling. Plastic injection molding is a process that utilizes heated barrel injection to fill an engineered mold with plastic. The liquid plastic is forced into the cavity of the accurately designed mold, cooled until solidified, and then removed, creating a three-dimensional product. By manipulating heat and pressure, this method can reliably mold a variety of products with speed and accuracy.

I got my new mold in today. Everytime I've ordered something from these guys, I've been impressed with the speed of shipping. They don't charge a penny for it, and I only have to wait 3-4 days before I'm playing with my new toy.

This is a sampling of injection tooling and molding materials we work with. See more information on available materials and specs here.

For faster creation of steel and aluminum molds for your parts, UPTIVE utilizes state-of-the-art equipment including high-speed 5-axis CNC machines, EDM, and surface and form grinders. We also give you the ability to create custom mold bases for intricate or high-volume projects. Our systems are made to generate quick-turn parts that meet your standards of exactness, robustness, and lightness while featuring complex part geometries suitable for injection molding.

Torn between getting the basstackle injector or the bears injector.Both seem really good, and I am getting a 5.25" injection stik mold from Del's and was wondering which would be best.

a buddy won 350 bucks last weekend as a nonboater in his club tourney on the ohio river using that craw your holding in your hand i make for him, great action and looks great on a jig. if it works on the ohio its got to be good.

If I'm not mistaken, Bob is a part of the company and has always provided good prices per cavity, quality and service. I've been using more and more Lurecraft silicone molds also. Again good prices and service.

Per cavity pricing is GREAT also!!! I just got some custom designed molds made and had them all in 7 days, Shipped FREE!!

If I'm not mistaken, Bob is a part of the company and has always provided good prices per cavity, quality and service. I've been using more and more Lurecraft silicone molds also. Again good prices and service.

You can post now and register later. If you have an account, sign in now to post with your account. Note: Your post will require moderator approval before it will be visible.

Per cavity pricing is GREAT also!!! I just got some custom designed molds made and had them all in 7 days, Shipped FREE!!

Torn between getting the basstackle injector or the bears injector.Both seem really good, and I am getting a 5.25" injection stik mold from Del's and was wondering which would be best.

why does your tips keep falling off? only had that happen once early last year and i learned from that 1 experience and never looked back!! the ease of cleaning the tube and tips out beofre the next round of molds is priceless thats why ill never use any other injector than bears!! they definitely arent for the begineer if they dont use some common sense beforehand!!

I admire the detailed machining in his swim bait molds. I personally don't own one, but I am in awe by the details that he has programmed into his molds.

Torn between getting the basstackle injector or the bears injector.Both seem really good, and I am getting a 5.25" injection stik mold from Del's and was wondering which would be best.

My son does some parts designing for his company for there cncs and he sees the molds and says his programmer in no way shape or form can even come close to what is in those molds. You being in that part might know is that a program or is it the person programming those details? As many people already know Kevin can produce a mold from an email in just a few hours. How I dont know but he has done it for me and many others that have told me. Bears mold maker has that talent also just take a look at his hollow swim and you can see it. Getting X Y and Z to flow like that is a great thing for us to make some of the best baits out there. Like I said before this is great for all of us. Frank

why does your tips keep falling off? only had that happen once early last year and i learned from that 1 experience and never looked back!! the ease of cleaning the tube and tips out beofre the next round of molds is priceless thats why ill never use any other injector than bears!! they definitely arent for the begineer if they dont use some common sense beforehand!!

I admire the detailed machining in his swim bait molds. I personally don't own one, but I am in awe by the details that he has programmed into his molds.

I agree, It takes a great imagination, and a total understanding of programming & machining to produce molds of that caliber.

Our team of experts will guide you through the process and accelerate your timeline with rapid turnaround on injection molded parts.

I have the Bears two color injectors,and I have tried my best to keep mine from coming out,I push it up against the pyrex cup on a angle and have done everything I now to do and mine still come out.Iv'e considered making a stand with holes the size of the injector tips,so I could push against them to empty my injectors in the cups.I really like every thing else that Iv'e bought fron Bears,and He is a great guy to deal with.I just wish the injectors did not have a hair trigger on them popping out.Iv'e used his single injector for some time now and have no problem uing them,but two color has been some thing else.I read this site most every day and read that a lot of people prefer the no pin injectors but I have tried and tried to get a handle on using the two color injectors and still have not got it done.

I have had the Basstackles Twinjector since before it had pins to hold the tips on. Now that was a pain to eject the plastic from two at the same time, one always came out. I posted the fix in an email to him and he imediatly saw the advantage of this simple fix. From then on he has incorperated it into all of his injectors. It takes no time at all to get use to the tip, with the slight turn it comes off and a slight turn back and it will never fall off. Yes his two color system has more parts but the convinience of filling two colors at the same time saves alot of greif. Kevin does listen to his customers and is willing to make changes to his products, for us the end user. You can see by the molds that he is producing he is listening. That is good for us all. Frank

I find the injector extremely easy to clean after each pour and don't have to worry about the tip falling into the hot plastic. Next time I need a new mold, BassTackle will be the first place I'll look.

I agree with you 100%. I have three BassTackle molds, and one of their injectors. Although I'm new to pouring, I find using their molds and injectors a pleasure to use.

I agree, It takes a great imagination, and a total understanding of programming & machining to produce molds of that caliber.

Most compatable, Easy to use, And clean, Etc. Is there anything I will need with the injector like an adaptor for the Del's mold new to this stuff haha

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly