Your Guide to Injection Molding Overmolding - over molding

Author:gly Date: 2024-10-15

Plastic injection molding offers diverse capabilities for a wide range of industries. In addition, advances in technology will continue to help manufacturers optimize the quality, sustainability, and adaptability of injection-molded parts.

The use of recycled polymer provides injection moulders and other manufacturers with the ability to realise significant cost savings over the use of virgin material, whilst manufacturing a more environmentally friendly and highly marketable product.

Enva is one of the UK’s leading plastic recyclers, recycling around 80% of the plastic from mixed WEEE (waste electrical and electronic equipment) derived from Small domestic appliances such as toasters, kettles and vacuum cleaners. This consistent input material combined with the latest technologies enables Enva to produce extremely high-quality recycled polymers. All our material is REACH and RoHS compliant and material safety data sheets technical data sheets can be supplied on request.

Topic: polymer manufacturing, injection molding, polymer components

OEMs across industries have many options for producing plastic components built to handle critical challenges. However, the benefits and best use cases among them vary considerably.

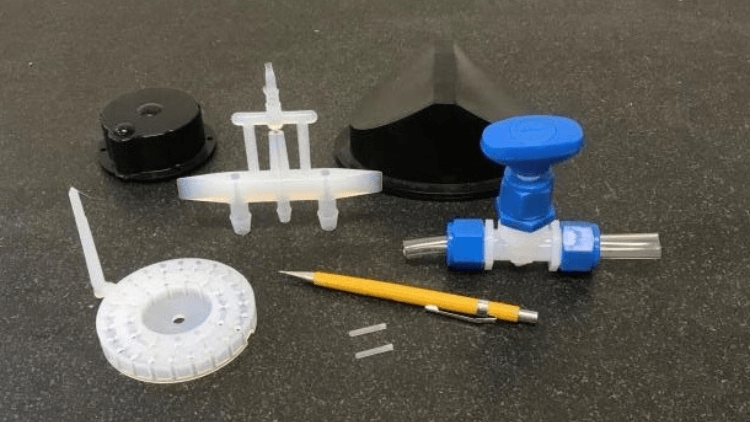

In the injection molding process, machines inject molten polymer materials under high pressures and speeds into closed molds, resulting in high volumes of identical components that meet rigorous mechanical requirements.

PP polymers produced by Enva customers include pipe parts, school chairs, under bonnet applications, automotive parts, kitchen unit sockets, coat hangers, plastic drums, buckets, baskets.

At Enva we use cookies to provide an enhanced website experience, obtain audience insights, and customise adverts and content you see across websites and social media.

PS & HIPS products produced by Enva customers include plant pots, coat hangers, mushroom trays, seed trays, planting troughs, footwear, wall plugs, cable caps, cable reels, storage contains, waterproof drums, fastening lips, identification tags, keyrings.

Cookies contain small amounts of information and are downloaded to your computer or other device (computer, smartphone, etc) by a server for this website. Your web browser then sends these cookies back to this Website on each subsequent visit so that it can recognise you and remember things like your user preferences. when you first visit a website. You can choose to not allow cookies used but blocking some cookies may impact your experience of the site.

In this blog post, we examine nine key characteristics of injection molding for complex polymer components. We also take a closer look at which projects are best suited for injection molding.

ABS products produced by Enva customers include furniture fixtures and fittings, cable reels, pencil sharpeners, plastic drawers, under bonnet applications, automotive parts, cupholders, gear sticks, plastic container, kitchen unit feet, licence plate backing, TV housing, keyboards.

A manufacturing partner with expertise across all phases of the process – from materials selection to part design and testing through to manufacturing – is essential to a successful outcome. When considering a partner, ask these questions:

Alternatives to injection molding include extrusion, blow molding, thermoforming, machining, and 3D printing – each with its own advantages. But if the project calls for precise capabilities, few processes deliver the quality and efficiency of injection molding.

For manufacturers of commodity and technical products, the realisation of these benefits can be almost immediate. Recycled plastic has no impact on product quality and can be substituted into manufacturing processes without the need for additional process modifications or lengthy testing periods.

Injection molding is remarkably versatile, and OEMs often gain efficiencies as well as cost savings over other plastic manufacturing processes. For OEMs with complex design requirements and no room for error, injection molding provides several advantages.

Across industries and critical environments – from industrial and aerospace to automotive and medical – injection molding is a proven go-to solution. However, not all projects benefit from injection molding efficiencies. Projects that are ideal for injection molding typically involve:

Enva provides recycled Polypropylene (PP), Polystyrene (PS), High Impact Polystyrene (HIPS), and Acrylonitrile Butadiene Styrene (ABS) polymers to manufacturers across the UK. By purchasing directly from Enva customers can benefit from additional cost savings.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly