What is HDPE Molding? Properties & Applications - Kemal - hdpe plastic injection

Author:gly Date: 2024-10-15

By being careful with all these variables of molding plastic at home (involving a plastic injection process), it is possible to achieve excellent results in the parts produced. In this sense, the search for knowledge, constant updating, and security are essential points that make the difference in positioning your company in the market.

Ready to elevate your HDPE injection molding projects to new heights? Contact Kemal Manufacturing today, and let us bring your ideas to life with precision, reliability, and unmatched quality.

Explore innovative mold cooling technologies like conformal cooling systems. These systems use advanced cooling channels that conform to the shape of the mold, providing more efficient and uniform cooling.

Applying suitable coatings or surface treatments, such as chrome plating or nitriding, can enhance the mold’s lifespan and facilitate easy part release.

Floor 1-3 of Changhong Technology Co. LTD , No 3. Jinglong Avenue, Shahu Community, Biling Street, Pingshan District, Shenzhen, Guangdong, China

You can assess the mold’s performance during molding. This can include injecting a test material into the mold and evaluating factors such as material flow, filling behavior, cooling efficiency, and ejection of the molded parts.

This is performed using various tools such as calipers, micrometers, height gauges, and coordinate measuring machines (CMM).

Transparency – LDPE is more transparent than HDPE. HDPE has a translucent appearance, while LDPE allows more light transmission, giving it a higher degree of transparency.

With blow molding, a hollow HDPE product is created. The process starts by extruding a tube-like parison of molten HDPE. It is then placed in a mold, and the air is blown into it, causing the material to expand and take the shape of the mold.

Selecting the appropriate mold materials is crucial for HDPE molding. High-quality steels, such as hardened tool steels, are commonly used due to their durability and resistance to wear and corrosion.

Strength and Stiffness – HDPE has higher tensile strength and stiffness than LDPE, making it more suitable for applications requiring greater structural integrity and dimensional stability.

Heat Resistance – HDPE exhibits better heat resistance than LDPE. HDPE has a higher melting point and can withstand higher temperatures before softening or deforming.

Chemical Resistance – LDPE and HDPE exhibit good resistance against many chemicals, making them suitable for applications that involve contact with various substances.

Blow molding and rotational molding may have longer cycles due to cooling and curing processes. Select a process that aligns with your time requirements.

This technology allows you to identify deviations or variations during molding and make necessary adjustments to maintain consistency and quality.

The plastic injection molding machine is easy to influence by items such as distribution channels, cold wells, and temperature uniformity. Composed of steel, the mold tool can contain mobile or stationary plates, which define the shape of the produced part.

HDPE molding involves melting and injecting material into a mold cavity to create a specific shape. This process has revolutionized making products such as containers, PET bottles, and automobile parts. You can use it for the manufacturing of a bottle or container.

Consider your product’s desired quality and surface finish. Injection molding typically provides precise dimensions and smooth surface finishes.

By following these restrictions and precautions, you can minimize the risk of defects and achieve high-quality finished products.

Physically, HDPE is lightweight yet sturdy, providing an excellent strength-to-weight ratio. It retains its shape and dimensional stability even under extreme temperatures, making it suitable for diverse environments.

Blow molding and rotational molding may have slight variations and surface texture. Assess which process can meet your quality expectations.

HDPE is a thermoplastic acknowledged for its versatile usage, exceptional durability, strength, and chemical and moisture resistance.

It is in the mold that the final part is created; that is, it is necessary to pay attention to quality throughout the injection process. The temperature has a great influence in this sense, as it can interfere with the part's finishing, internal tensions, dimensional stability.

A good, molded part requires basic principles such as knowledge of the physical properties and processing characteristics of the material, in addition to adjusting the equipment at the appropriate temperatures for the cylinder and mold.

Consider the required production volume. Injection molding is efficient for high-volume production, while blow molding and rotational molding are often used for medium to large production quantities.

Techniques such as ultrasonic testing, dye penetrant inspection, and magnetic particle inspection can be employed to identify cracks, surface defects, or hidden flaws within the mold structure.

These two commonly used polyethylene materials share some similarities but also notable differences. Some are discussed below:

Processability – HDPE is generally easier to process than LDPE. HDPE exhibits better flow properties, making it more suitable for injection molding or blow molding.

Each step requires a certain temperature to work well. As we can see, the higher the temperature, the more there is contraction and degradation of the material. Likewise, the holding pressure influences the filling and burr creation of the parts. Pay attention to the ideal balance for safe, quality plastic injection.

The HDPE molding process encompasses various techniques, each serving specific purposes. To end your curiosity, let’s look at three commonly used HDPE molding processes: injection molding, blow molding, and rotational molding.

It is advisable to avoid abrupt changes in wall thickness, as this can lead to uneven flow and potential defects in the final molded product.

HDPE exhibits notable chemical and physical properties. It can tolerate chemical solvents, withstand corrosion, and survive dampness. It resists the effects of acids, bases, and other substances, preserving its life and robustness.

These include scratches, blemishes, or uneven texture on the molded part’s surface. It can arise due to contamination in the material, mold surface imperfections, inadequate mold cooling, or improper mold release agent application.

After cooling, the mold is opened, and the final blow-molded HDPE product is released. This process is frequently used to create hollow things like bottles and containers.

These methods help ensure that the mold surface is free from imperfections, scratches, or roughness that may impact the quality of the molded parts.

Understand the specific material properties of HDPE that your product requires. Consider factors like strength, durability, chemical resistance, and flexibility.

All three molding processes can accommodate HDPE, but certain properties may be more relevant to one process than the others.

You can identify any potential issues or defects in molds by employing these inspection and testing methods, allowing for timely corrective actions and ensuring the production of high-quality molded products.

Use simulation software to model and simulate the HDPE molding process. This technology lets you virtually test different mold designs, process parameters, and material properties before production, helping you optimize the process, reduce trial and error, and minimize waste.

In this process, HDPE pellets are melted and injected into a mold cavity using high pressure. Once inside the mold, the molten HDPE solidifies and takes the shape of the mold.

You’ll find it suitable in processes including blow molding, injection molding, and extrusion to manufacture a wide range of products such as pipes, containers, bottles, automobile parts, and toys.

In addition to drying time and material temperature, pay attention to mold temperature control, rework after injection. Apart from these in molding plastic, temperature control and cavity filling, in the case of molds with hot runners, also link.

Mold protection is worth mentioning that all injection molding machines include mold protection from the oldest to the newest. When done properly, it helps to ensure efficient injection of thermoplastics.

The selection and positioning of gating and ejection systems impact the flow of HDPE material and the ejection of the finished part. Proper gate design ensures uniform material flow into the mold cavity, minimizing the risk of flow lines, air traps, or part defects.

Surface analysis methods, such as profilometry and microscopy, can be used to examine the surface finish and texture of the mold.

Evaluate the design requirements of your product. Injection molding suits intricate and detailed designs, while blow molding is ideal for hollow objects. Rotational molding is well-suited for large, seamless products.

It is also necessary to control the backpressure, which allows for greater homogenization and gas elimination. Its poor management can lead to degradation, breakage of the molecular chain, detachment of fibers, or even a reduction in the useful life of the cylinders.

Blow and rotational molding may have lower tooling costs but are suitable for specific product types and production volumes.

Rotational molding involves rotating a hollow mold while heated HDPE resin is gradually melted and coated on the inner surfaces of the mold. The mold rotates as the melted HDPE cools and solidifies, forming the desired shape.

Utilize advanced monitoring and control systems that provide real-time data on key process parameters such as pressure, temperature, and cycle times.

Low Impact Strength at Low Temperatures: It exhibits reduced impact strength at low temperatures, becoming more susceptible to cracking or failure under impact or cold weather conditions.

Maintaining uniform wall thickness throughout the part promotes even cooling and minimizes the risk of warping, sink marks, or uneven shrinkage.

To achieve greater precision in the positioning of the spindle and repeatability in the metering volume, it is generally advisable to adjust the metering profile with higher initial speeds. This number decreases as the cylinder is loaded and during cooling to increase cylinder life and prevent raw material degradation.

Assess the cost implications of each molding process. Injection molding typically requires upfront tooling costs but offers high production efficiency, making it cost-effective for large volumes.

Good results also involve the safety of plastic injection molding operators. Therefore, it is important that your company is aware of and adequate to the security requirements.

Generally, molding plastic at home's pressure must be scaled down. In this way, when the injected solidifies, internal tensions avoid. However, this must come with caution because sudden drops before the gate freezes can cause the material to return to the cylinder, which causes material reorientation.

These are depressions or indents on the surface of the molded part. They occur when the material experiences uneven shrinkage during cooling, resulting in localized depressions.

It refers to the distortion or deformation of the molded part from its intended shape. It can occur due to non-uniform cooling, inadequate cooling time, improper mold design, or excessive internal stresses in the material.

Robots can handle material handling, part ejection, and quality inspection, allowing for faster production and consistent output.

HDPE (High-Density Polyethylene) is a versatile material widely used in various industries to produce different products.

The mold is opened once the cooling process is complete, and the final rotational-molded HDPE product is extracted. This method is suitable for creating large, seamless, durable products like tanks, bins, and playground equipment.

While HDPE (High-Density Polyethylene) has numerous advantages for molding applications, there are a few disadvantages to consider:

These are air pockets or gaps within the molded part. You’ll witness them resulting from inadequate venting, poor material flow, or entrapped air during the injection.

Evaluate the desired time-to-market for your product. HDPE injection molding generally has faster cycle times, allowing for quicker production and turnaround.

Integrate robotics and automation into your HDPE molding process. Automated systems can streamline operations, reduce human error, and increase efficiency.

Additionally, HDPE is known for its low friction coefficient, making it ideal for applications requiring smooth surfaces.

Consider using energy-efficient machinery and equipment for molding. Upgrading to more efficient motors, heaters, and cooling systems can reduce energy consumption, lower operational costs, and contribute to environmental sustainability.

Careful consideration should be given to the mold design, including using slides, lifters, or collapsible cores to accommodate undercuts and complex geometries.

Initially, it is necessary to carry out a previous and detailed study of the thermoplastic resin to be common, according to what you want to obtain as a final product. In molding plastic at home remember that each resin belongs to a family, which in turn counts certain amounts of grades.

When it comes to optimizing your molding process, several technologies can help you achieve better results. Consider implementing the following:

Several important mold considerations can greatly impact the final product’s overall process and quality. Here are key factors to keep in mind:

Moreover, HDPE is flexible, allowing easy bending and shaping during molding. It demonstrates high impact resistance, ensuring resistance to fractures or cracks.

The final material is then pushed out of the mold via ejector pins. A coolant (usually water) passes through the material to remove some of the heat and prevent overheating. For molding plastic at home not to impair the proper functioning of the mold, it is important to consider the following items:

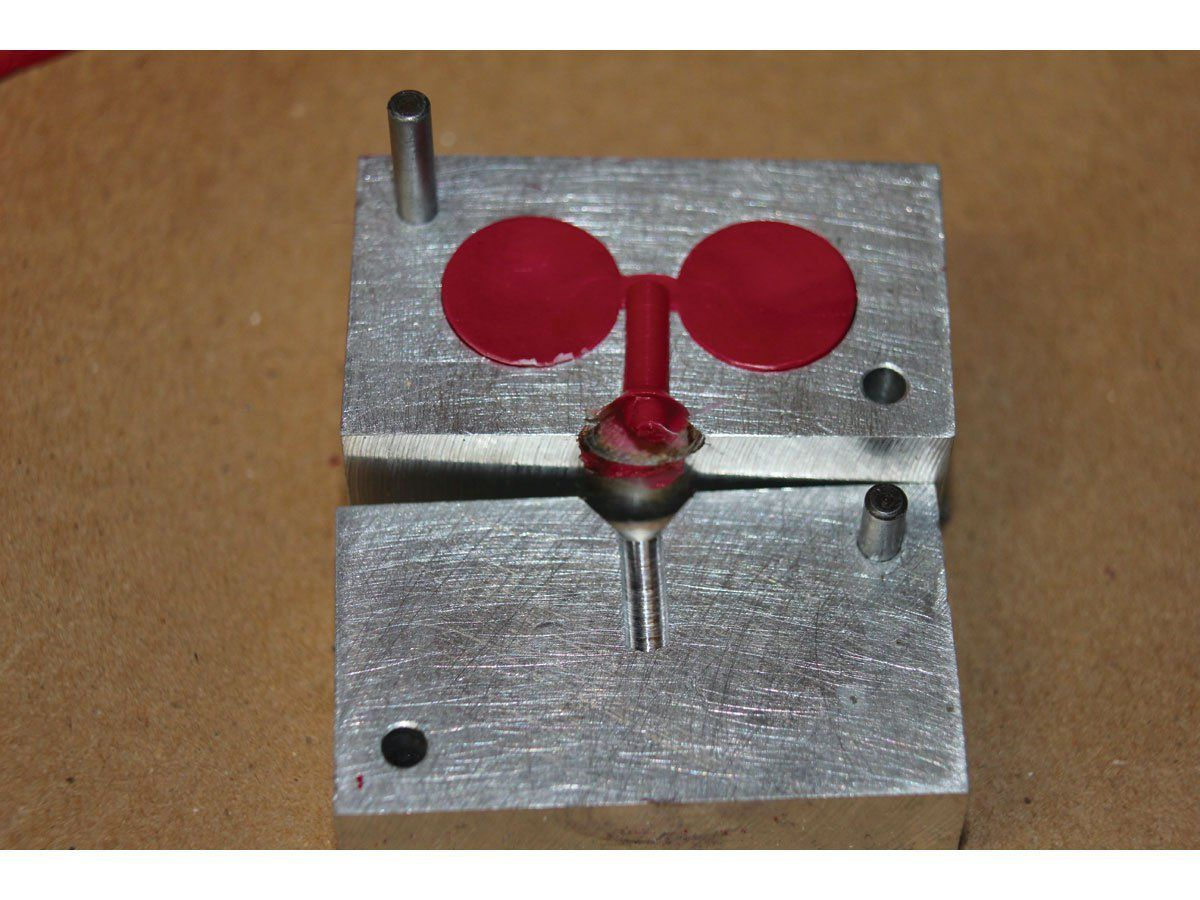

It serves to absorb the colder flow in front of the material. The machinery is usually composed of a primary cold well and a secondary one. See below for an example of a cold well distribution channel. This links to molding plastic at home

Draft angles allow for the smooth release of the part from the mold cavity without causing damage or deformation. Adequate draft angles also facilitate proper material filling during the molding process.

The desired shape is subsequently achieved when the molten HDPE hardens in the mold. The finished item is then evacuated after the mold has been opened.

The benefits of HDPE are not limited to strength, chemical resistance, toughness, and moisture resistance, but you’ll find it economical, sustainable, and eco-friendly.

When the final portion has cooled, the mold is opened, releasing it. With HDPE injection molding, you can produce intricate and detailed products with high precision and consistency.

While using HDPE for molding, you must be aware of certain constraints and take the needed precautions to achieve a successful molding activity.

Invest in material testing and characterization equipment to analyze the properties of the HDPE material. This technology helps ensure the material meets the required specifications, allowing for better process control and optimized part quality.

You should consider factors such as part geometry, wall thickness, draft angles, gating and ejection systems, and venting. The mold construction should also be robust and precise to withstand molding pressures and temperature cycles.

First, it is important to know that the drying time of the molded material directly affects its final strength. Thus, once the ideal drying time is respected, the greater the resistance of the piece. Another highlight of molding plastic at home is the temperature and pressure common in the injection process.

As you can see, there are many more variables involved in the injection process than mold and raw material/material variables. Therefore, it is necessary to be extra careful with the process to guarantee the quality and performance of the final product.

This makes it a popular choice for plastic product manufacturers. So, to unlock a world of creativity and use, embrace choices offered by HDPE molding.

For HDPE molding applications, injection molding is the best option because it guarantees exact control over dimensions, good surface polish, and repeatability.

We can say that three main factors directly influence the quality of the molding plastic at home: the mold, the material (raw material), and the process. We'll talk about them in this article. Also, get to know some points of attention that are needed during the injection process

This article will lead you to knowledge about High-Density Polyethylene (HDPE) and a few of its numerous applications. You may be working as a product designer or an engineer or have an interest in plastics, increasing your views and scope of options.

It refers to excess material that protrudes from the mold’s parting line. Flashing occurs when the mold does not close properly, leading to material escaping between the mold halves.

Regular maintenance is essential to keep the mold in optimal condition and prolong its lifespan. This includes routine cleaning, inspection, lubrication of moving parts, and addressing signs of wear, damage, or parting line mismatch.

Yes, HDPE can be injection-molded. It is a commonly used technique for shaping HDPE into various products. HDPE pellets are melted and injected under intense pressure into a mold cavity during the injection molding.

It involves a thorough visual examination of the mold surface, components, and critical areas to identify any signs of wear, damage, or defects.

Density – The primary difference between LDPE and HDPE is their density. LDPE has a lower density, typically ranging from 0.910 to 0.940 g/cm³, while HDPE has a higher density, typically ranging from 0.940 to 0.970 g/cm³.

Susceptibility to UV Degradation: HDPE is vulnerable to UV degradation when exposed to prolonged sunlight or ultraviolet radiation. This may result in the material’s brittleness, color fading, or surface cracking over time.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly