What Is LSR 2-Shot? Your Guide To Multishot LSR Molding - double shot moulding

Author:gly Date: 2024-10-15

Fast Part Quote and Molding Low Cost, Quick Build, and Good Quality Online Project Management Trouble-Free Part Modifications No Size Limitations Any Commercially Available Material and most standard Surface Finishes

Prototype injection molding produces real injection molded parts for functional testing. Injection molding prototyping can also serve as bridge tooling to fill the manufacturing gap before production tooling or when production tooling goes down.

American Injection Molding, Inc. | Injection Molded Plastic | Home | Request for Quote | Photo Gallery | Privacy Policy/Terms of use | List of Companies | Sitemap

© Injection Molded Plastic will keep your information private and secure. We will not share your email address with any third parties.

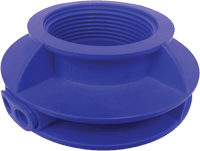

Rotational molding, commonly referred to as "rotomolding", is a plastic casting technique used to produce hollow, seamless, and double-walled parts. It uses a hollow mold tool wherein the thermoplastic powdered resin is heated while being rotated and cooled to solidify...

Thermoplastic molding is a manufacturing process that works to create fully functional parts by injecting plastic resin into a pre-made mold. Thermoplastic polymers are more widely used than thermosetting...

Prototype production is a necessary part of the injection molding industry because the costs associated with producing a prototype are significantly less than going straight to large scale production. Injection molding prototyping is a tried and true method for ensuring the mold is accurately designed prior to reproducing hundreds, thousands, or even millions of parts. Nothing can compare to the feeling of confidence that comes with holding a nearly finished version of your product before entering the production phase. This will ensure what you have designed and engineered will be exactly what you receive.

We offer assembly and finishing services to provide complete solutions to our customers. These services include post-mold machining, ultrasonic welding, printing, and packaging. Our comprehensive capabilities allow us to deliver fully finished products ready for market.

Polyurethane molding is the process of fabricating or manufacturing plastic parts by introducing a urethane polymer system into a tool or mold and allowing it to cure. Like any other type of plastic, the excellent processability...

A plastic gear is a toothed wheel made up of engineering plastic materials that work with others to alter the relation between the speed of an engine and the speed of the driven parts. The engineering plastic materials used in manufacturing plastic gears can be...

Provide your project details, and we'll connect you to 5-20 qualified injection molded plastic companies in your region. 100% free.

Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or preform. The parison...

Plastic overmolding is a manufacturing process that involves combining two or more plastic materials to create a single, unified part. The process enhances the functionality, durability, and aesthetics of plastic components by...

A prototype mold is essentially the same as a production mold. It can produce the same parts as a production mold but is only warrantied for 10,000 cycles. Production molds will typically last for 100,000 cycles or more. The only real difference between prototype molds and production molds is the mold material. Prototype molds are made of softer steel that is easier to cut but does not last as long. ICOMold’s production molds are all made with high-strength steel and built to last.

Many of the products used daily are made possible by producers and suppliers of rubber and plastic. These substances are robust, adaptable, and capable of practically any shape required for various industrial purposes...

American Injection Molding, Inc., located in Greensboro, NC, is a leading provider of injection molded plastics products and services. With a commitment to quality, innovation, and customer satisfaction, we specialize in delivering high-performance plastic solutions to various industries.

Urethane casting is the process of injecting polyurethane and additive resins into a soft mold usually made of silicone elastomer. The casting process is similar to injection molding; injection molding differs by using hard, metal molds...

Plastic injection molding, or commonly referred to as injection molding, is a manufacturing process used in the mass fabrication of plastic parts. It involves an injection of molten plastic material into the mold where it cools and...

Quality is a top priority at American Injection Molding. We have established a robust quality management system to ensure the highest level of product quality and customer satisfaction. Our quality control team conducts rigorous inspections and tests throughout the manufacturing process to guarantee that every product meets or exceeds industry standards.

American Injection Molding, Inc., located in Greensboro, NC, is a leading provider of injection molded plastics products and services. With a commitment to quality, innovation, and customer satisfaction, we specialize in delivering high-performance plastic solutions to various industries.We offer a wide range of injection molded plastics products that are designed to meet the diverse needs of our customers. Our state-of-the-art manufacturing facility, advanced technology, and experienced team enable us to produce precision-engineered parts with exceptional quality and consistency. We have extensive expertise in producing custom injection molded plastic parts to meet the specific requirements of our clients. Our skilled team works closely with customers to develop and manufacture parts that align with their unique design specifications, functional needs, and aesthetic preferences. From small, intricate components to large, complex assemblies, we have the capabilities to deliver precise and reliable solutions.We offer assembly and finishing services to provide complete solutions to our customers. These services include post-mold machining, ultrasonic welding, printing, and packaging. Our comprehensive capabilities allow us to deliver fully finished products ready for market.Quality is a top priority at American Injection Molding. We have established a robust quality management system to ensure the highest level of product quality and customer satisfaction. Our quality control team conducts rigorous inspections and tests throughout the manufacturing process to guarantee that every product meets or exceeds industry standards.

Prototype plastic injection molding can be done very quickly. The initial part will have the shape and functionality a plastic prototype part would need for testing form, fit, and function, but may not have fine details like color or surface finish preference. Prototype molds are built to handle minimum of 10,000 cycles.

We offer a wide range of injection molded plastics products that are designed to meet the diverse needs of our customers. Our state-of-the-art manufacturing facility, advanced technology, and experienced team enable us to produce precision-engineered parts with exceptional quality and consistency. We have extensive expertise in producing custom injection molded plastic parts to meet the specific requirements of our clients. Our skilled team works closely with customers to develop and manufacture parts that align with their unique design specifications, functional needs, and aesthetic preferences. From small, intricate components to large, complex assemblies, we have the capabilities to deliver precise and reliable solutions.

The current manufacturing trend is to use 3D printing to produce prototype parts. While 3D printing is a quick and efficient way to produce prototypes, it does have some serious drawbacks. Material choice is the biggest limitation when using 3D printing for prototypes. 3D printing can only use very specific materials that may not hold up to the demands of testing. Prototype injection molding will produce usable parts in the same material as the final part. This will allow designers to test the form, fit, and function of the part without worrying about differences in the material characteristics.

All projects are assigned a dedicated project manager and engineer to ensure your prototype injection molding project is done on time and in budget. For more information, please check out ICOMold’s Online Project Management System.

ICOMold’s fast-turn, low-cost, high-value injection molding enhanced by joining Fathom’s manufacturing platform. Learn More

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly