What is Precision Injection Molding? - high precision plastic injection molding

Author:gly Date: 2024-10-15

The hot runner vs cold runner debate is not new in the plastic components manufacturing industry. Each system has its unique range of advantages, disadvantages, and best choice of materials. The primary difference between these two systems lies in the pathway, or runner, whereby the molten thermoplastic travels from the heating cylinder to the individual molding cavities. Understanding the basics of injection moulding is key to choosing the right runner system, which is why we recommend reading our Injection Moulding Parts Basics for foundational knowledge.

Injection molding is one of the most widely used manufacturing processes, capable of producing intricate plastic parts with high precision. However, like any industrial process, it has its challenges, and…

All-Plastics works with a variety of medical industries to provide injection molding services to help create, design, and mold custom applications and parts. Some of the medical markets we serve are:

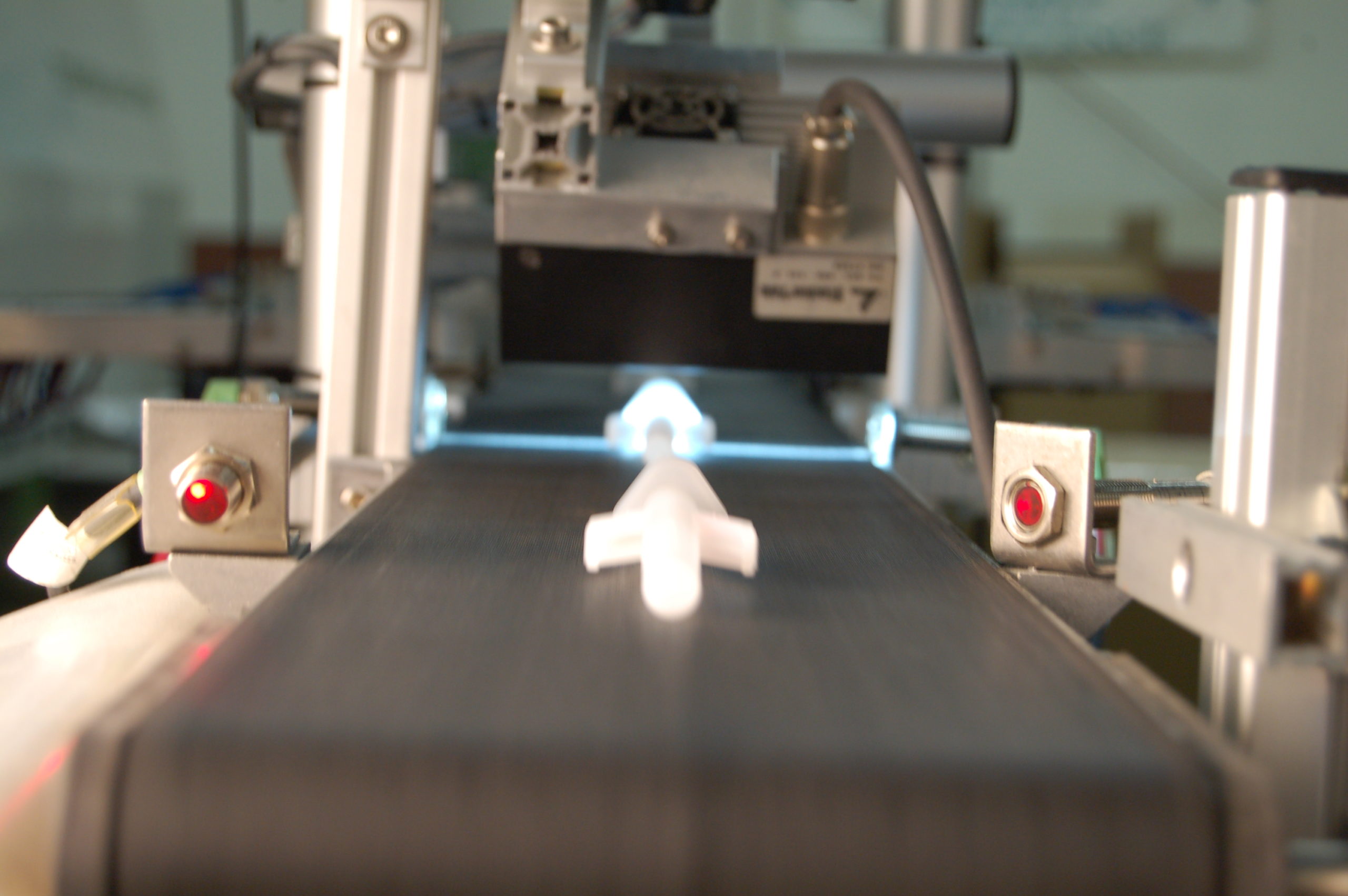

By employing advanced medical injection molding in our manufacturing process, we are able to supply high volumes of medical components without sacrificing quality while meeting your target specifications.

A cold runner system can potentially lead to slower cycle times – however, it does offer benefits. A significant one is that the manufacturing process is simpler, and the mold’s design and maintenance are less complex. This simplification may result in lower initial and maintenance costs, an enticing factor for many manufacturers.

All-Plastics has expertise in providing cost-saving, high quality injection molding solutions to the Medical Device industry. Our expertise in medical injection molding allow us to support tight tolerance micro-sized components to complete medical devices.

Hot runner molds bring with them a host of advantages. For starters, they lead to faster cycle times, making the manufacturing process significantly quicker. This system reduces the amount of scrap produced during the molding cycle, saving valuable resin and contributing to a greener manufacturing environment. A hot runner mold also allows for color changes and molding larger parts, widening the scope of manufacturing possibilities.

The insulated hot runner keeps the plastic material molten through the thermal insulation that envelops an unheated runner. On the other hand, the heated hot runner mold features an externally heated runner. The heating permits a uniform temperature throughout the molding cycle, ensuring consistent quality of the molded parts.

Within the injection molding domain, the hot runner mold embodies a popular system used in the formation of plastic parts. With a manifold system that’s heated, the hot runner mold ensures the plastic remains in a molten state through the entire molding cycle, from the nozzle to the mold cavities. This approach can lead to faster cycle times, thereby speeding up the manufacturing process.

Cold runner systems come in two primary forms: two-plate and three-plate systems. The two-plate system is the simpler of the two; it uses a single parting line, allowing the plastic material to enter the mold on one side. While it has fewer moving parts, this system can only manufacture less complex plastic parts.

If your smartphone has a clear, durable casing, it's likely made of polycarbonate. This thermoplastic polymer is a popular material among plastic parts, components, and products manufacturers. Its qualities, such…

In the end, understanding your project’s unique requirements and the characteristics of your desired plastic parts is key to making an informed decision.

All-Plastics caters to your need for durable plastic medical components that comply with strict FDA standards and regulations.

However, it’s not just about speed. The hot runner approach is also about efficiency. The molten material travels straight from the heating cylinder to the mold cavities without leaving any scrap, fundamentally different from the cold runner system.

Despite the slower cycle times, both the insulated and heated hot runner systems have their merits and drawbacks. Understanding the performance of each is crucial to deciding the best option for a specific manufacturing process.

Cold runner molds provide several benefits, one of which includes low startup costs—the simpler design and functionality mean a less-expensive mold and lower maintenance costs. Cold runner molds also offer more flexibility. They can be used with heat-sensitive polymers or those that may degrade in hot runner systems. Plus, color changes are easier and faster in cold runner molds since there’s no risk of leaving behind molten material.

Our experts provide Project Management solutions from Concept to Operational Excellence, including full program documentation and component traceability. REQUEST A QUOTE

That’s where expert services like those provided by Aco Mold can prove invaluable. Specializing in custom injection molding services, Aco Mold can offer guidance and expertise to help you navigate the technical details. The breadth of their experience with both hot runner and cold runner systems means they can cater to your specific needs effectively and professionally, whether your goal is high volume, faster cycle times, or a more budget-friendly solution.

The type of molded part or product you want to produce is crucial when selecting the right runner system. Hot runner systems, thanks to their efficient cycle times and material usage are often used for the high-volume production of plastic parts, especially in precision industries like automotive and medical instruments. They’re more suited for manufacturing larger parts and components that require exact dimensional stability.

That said, there are cons to consider. For instance, the initial setup cost of a hot runner mold is higher than that of their cold runner counterparts, which can deter manufacturers who are mindful of initial expenses. Besides, the technical complexities of maintaining a hot runner system can increase the overall operation cost.

Injection molding, a manufacturing process frequently used in the production of plastic parts, uses varying systems to achieve its purpose. The main categories are hot runner and cold runner systems, also called hot runner molds and cold runner molds, respectively.

In contrast, the three-plate system employs two parting lines, offering the advantage of simultaneous ejection of the molded part and the runner. The three-plate system can mold more complex, yet smaller, plastic parts with ease. However, the intricacies and additional moving parts could lead to slightly increased maintenance efforts.

In the hot runner mold system, the plastic injection molding process results in no wasted resin, thus offering another form of efficiency: material use. Therefore, with hot runner molds, you can anticipate minimal material waste, effective use of energy, and quicker cycle times.

All-Plastics employs a state-of-the-art plastic injection molding process in order to produce high-quality medical products that meet the strict guidelines set by regulatory bodies. This ensures the safety and efficiency of all manufactured medical products and tools, which include:

Deciding between a hot runner and a cold runner system is not a straightforward choice; it hinges on several factors. The type of product you intend to manufacture, your budget constraints, the materials you’re planning to use, and the scale of production are crucial variables influencing the decision. Choosing between hot and cold runners depends on your manufacturer’s capabilities, as top manufacturers like those listed in our China Mold Manufacturer article often have advanced technologies.

Material selection and method of production are always key considerations in the manufacturing of products, devices, and components for the medical industry. This is because of the strict regulations and standards that govern the industry. Plastic injection molding meets these requirements and offers a wide range of benefits for the medical industry.

On the flip side, hot runner systems, despite their higher initial cost, usually have lower operating costs. They leave no runner waste, significantly reducing material costs. Faster cycle times also lead to higher productivity, appeasing those who emphasize efficiency and speed. Still, they require careful maintenance and can be more expensive in terms of energy consumption. Weighing initial investments against long-term benefits is key in the hot runner vs cold runner decision-making process.

Medical injection molding is a plastic molding and manufacturing process involving liquefied plastic into a mold to create plastic products of various shapes and sizes. In this process, the plastic is allowed to conform to the shape of the mold and harden to produce the desired finished product.

However, cold runner molds are not free from downsides. They produce more waste in the form of a solidified “sprue.” The slower cycle times could affect output rates, and the variety of moldable parts is somewhat limited. Balancing these pros and cons is key to choosing which system is the best fit for manufacturing requirements.

Our medical plastic injection molding and clean room molding production solutions that increase quality, security and provide cost advantages for the Medical Market are:

Yes, definitely. Material choice is an important consideration in the hot runner vs cold runner debate. Hot runner systems excel in working with a wider variety of polymers. High-temperature thermoplastics, for example, can maintain their molten state longer in a hot runner system, enhancing the final product’s consistency and quality.

The cold runner’s disadvantage lies within the production of scrap, as the leftover plastic in the runner is ejected with the final product, producing waste resin. Additionally, utilizing a cold runner system might restrict the types of thermoplastics you can work with, particularly heat-sensitive polymers.

A cold runner mold, unlike its hot runner counterpart, is not heated. The molten thermoplastic travels from the heating cylinder to the molding cavities via an unheated runner. This journey allows the molten plastic to cool and harden before being injected into the mold cavities.

Conversely, cold runner systems may be the best choice for handling heat-sensitive polymers. These systems prevent material degradation that can happen when such polymers are subjected to prolonged exposure to high temperatures found in hot runner systems. Thus, understanding your material’s characteristics will guide you toward the most suitable runner system.

Cold runner systems, with their easier handling of heat-sensitive polymers and simpler setup, are commonly seen in the production of smaller, less complex parts. They’re also the go-to choice for low-volume production scenarios and jobs requiring frequent material or color changes.

Hot runners keep the plastic in a molten state via heated runners, while cold runners allow the molten plastic to cool and solidify within unheated runners. Understanding the nuances of each system helps deliver the final product with the best quality.

The cost comparison of hot runner vs cold runner is reliant on several factors besides the upfront mold price. While cold runner systems are less expensive initially, their ongoing operational costs can increase due to slower cycle times and the need to recycle or dispose of the runner waste.

Both hot runner and cold runner systems have their rightful place in the intricate world of injection mold manufacturing. Hot runner molds offer swift cycle times, and minimal waste, and are ideal for large-scale production. On the other hand, cold runner molds provide a cost-effective alternative with easier color changes, making them perfect for heat-sensitive materials or smaller-scale operations.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly