White & Case Advises Husky Injection Molding Systems on ... - husky injection mo

Author:gly Date: 2024-10-15

Of course, the above is just a list of the common basic costs of injection molding. There are also costs such as shipping, overhead, taxes, and other shared costs that affect the final injection molding cost. These costs are taken into account by the injection molding company during the injection molding quotation process.

Proto Labs, Inc. 5540 Pioneer Creek Dr. Maple Plain, MN 55359 United States P: 877-479-3680 F: 763-479-2679 E: [email protected]

Our digital factories create prototypes and low-volume parts fast, while our manufacturing network, offers advanced capabilities and volume pricing.

The artificial cost is also included in the overall injection molding cost estimate. This cost is mainly the expenses involved in the related departments. In simpler terms, the costs created by one department by utilizing other departments’ services within a company or manufacturing setup are known to be the artificial cost.

If you’re opting for the injection molding process for shaping and manufacturing plastic and rubber items for your business, you may be curious to know ‘what is the injection molding cost estimate’? Generally, when you’re opting for any manufacturing process, it’s evident that multiple stages/processes, materials, and additional requirements may need funding for the manufacturing process to proceed and complete. Whether it’s the simple manufacturing of wooden tables or plastic and rubber materials used in different industries like tech, hardware, etc., producing anything and everything is only possible if you can fund it.

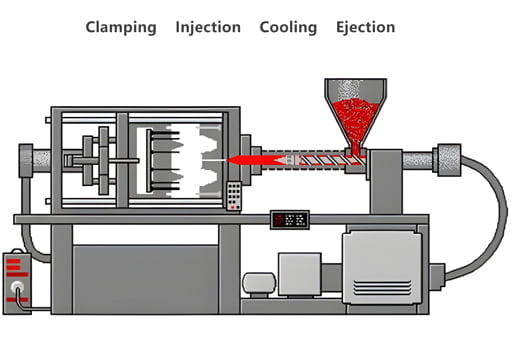

Once the ejection is completed, the mold can be shut down and used for another shot’s ejection process. In this final stage, the pressure and time taken to eject the mold is also a factor that should be considered to determine the cost of injection molding.

So how do you evaluate the injection mold cost? Let’s go ahead and explore the detailed overview of these costs and how you can evaluate them per each process involved in injection molding.

And varying on the production type, complexity, and expected final product, these costs can either be very minimum or a decent part involved in the overall injection molding cost.

Want to learn more about injection molding? Sign up to receive a Design Cube. This physical aid demonstrates how to properly design features commonly found on molded parts.

While the molds themselves are similar, part quantities, lifetime maintenance, quality documentation, and pricing vary depending on which service option is chosen. The right one depends on your project needs.

Now varying on the machine type and size, which depends on the project and how much clamping power the machine needs to incorporate on the mold halves, the time of closing and clamping the mold can be more or less. Simply put, larger machines may take more time, resulting in more plastic injection molding costs, whereas the smaller ones may cost less.

Nevertheless, Let’s look at the average cost of injection molds first. On average, the injection mold cost for small and simple cavity injection molds is around $1,000 – $5,000. However, as per the size extension and complexity of the molds, the injection molding cost can increase up to $80,000 or more. So different factors, processes, and types of expenses involved in the production process handled through injection molding can be different for different users.

Tough Black (Loctite Henkel 3843) and Ceramic-Filled (BASF 3280) are two new advanced photopolymer materials now available for 3D printing.

While this is a process of wooden table production and the different costs involved, manufacturing plastic or rubber items through the injection molding process also comprises multiple processes and relevant finance demands. Since the injection molding process is focused on shaping products by injecting heated material inside a mold, multiple products and processes involved in this manufacturing method are involved in the overall injection molding cost.

Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mold’s runner system. Hot resin is shot into the mold cavity through the gates and the part is molded. Ejector pins facilitate removal of the part from the mold where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

The manufacturing process for molded parts is complex. Before your parts are even molded, we're there to help you with comprehensive manufacturability feedback and consultative design services, so you can avoid mold design pitfalls before the resin hits the mold. From there, our production process is documented and optimized using scientific molding so you get high-quality parts consistently and reliably with every production run.

Another crucial factor to consider when evaluating the cost of injection molding is time. When you consider professional and reliable manufacturing companies that offer you various services and manufacturing process solutions like injection molding, they highly consider the time taken in the production process, varying on how long the machine is used. Simply put, manufacturing factories highly prioritize time when managing the injection molding process on a budget is an additional cost factor. Therefore, the time of an injection cycle is very important. That’s what we are about to talk about.

Depending on the type of machine, the pressure the machine invests on the part, and the time the machine runs, the electricity cost can differ for producing one or more parts of different kinds.

Nave ISK-8, Parque Industrial y Logístico Sky Plus, Avenida Mineral de Cinco Señores No.100, del Parque Industrial Santa Fe, Silao de la Victoria, Guanajuato, México

Our plastic injection molding process produces custom prototypes and end-use production parts with lead times as fast as 1 day. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock about 200 different thermoplastic resins.

We have wide selection of more than 100 thermoplastic and thermoset materials. And if you're looking for alternative material options, check out our guide to resin substitutes for ABS, PC, PP, and other commonly molded plastics.

When determining the overall cost involved in injection molding for any kind of project, it’s essential to consider each expense you will have to bear during the production process. From the raw material to the operation, and even the repair costs as well as tool costs, each factor collectively contributes to evaluating ‘how much does injection molding cost?’

Hence, understanding the injection molding cycle and the time each process takes can make it easier to plan the injection molding cost estimate to acquire this result. Does that sound like an intelligent plan to manage budget planning and financial investment? Then, let’s dive into the details of each stage and the time it takes!

Lastly, the final phase of the injection molding process is the ejection process. As the machine’s last process, this process is handled by the ejection system. The machine pushes the part out with force when the mold is opened. Force is mainly used in this phase to smoothly push the shrunk part that may have stuck to the mold.

When it comes to the injection mold cost involved in the cooling phase, evaluating the time taken by this phase is crucial. It can evaluate this time through the wall thickness and the thermodynamic properties of the plastic part. The longer or less time this phase takes, the faster or later the machine can stop working, and the mold can be opened.

It can be challenging to determine the estimated time to evaluate the injection molding cost involved in this phase. The main reason it had to determine the time and cost of the phase is the consistent changes in the flow of the plastic and its dynamic. However, it can evaluate the injection time if we consider other factors, including the injection pressure involved, the power applied by the machine varying on the project size and complexity, and the shot volume.

Our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall production time. View our design guidelines page for more details.

The material cost is one of the high costs that affect the overall injection molding process budget. The material used for the part is of immense value in the molding process. The use of high-quality material for handling the injection process in the machine promises quality outcomes for the product/part, including better strength, durability, shape, and size.

Once the cooling period has elapsed and the part has wholly taken its form, the mold can be reopened in the final stage.

Another crucial factor to consider when evaluating the cost of injection molding is the electricity expense. Since the entire injection molding process is carried out by machinery, electricity consumption is also exceeded.

As we all know, mold is the premise of the injection molding process. When the amount of products produced by injection molding is large, the mold cost may be negligible. But when the amount of injection molding products is small, mold cost will be a large part.

Critical-to-quality (CTQ) dimensions you call out on models let us know what areas are most crucial to the success of your parts. Once the parts start molding, the process and samples are qualified using automated inline CMM technology, generating a detailed FAI and process capability study with no additional lead time.

Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.

The second phase of the injection molding process is the injection phase. In this phase, the plastic pellets are fed to the mold using a hopper in the injection molding machine. The injection unit in the machine pushes these pellets toward the mold.

In addition, additional production factors and demands like product complexity, expected production quality, material, and the product’s size also contribute to extending or minimizing the costs.

In addition, the type of mold used in the machine is also involved in the material cost, as it affects the quality of the finished product.

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.

It's most often used for the manufacturing plastic parts at scale due to its low material waste and low cost per part. It’s an ideal manufacturing process for industries like medical devices, consumer products, and automotive.

Our thermoplastic injection molding is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. As part of the scientific molding process, our molders independently optimize and monitor fill speed, hold pressure, and hold time, and periodically inspect part quality and cosmetics. During the molding process, we use an automated inline CMM to ensure dimensional accuracy, as well as generate a detailed process capability study and FAI report.

This complete reference guide walks you through everything from quoting, design analysis, and shipment to best practices that ensure your model is optimized for molding.

Now the injection pressure usually ranges from 35-140 MPa. At the same time, you can evaluate the additional two factors by reading the hydraulic system in the machine once you complete the injection process for one product.

Next up is the cooling phase involved in the injection molding process. This phase involves cooing the plastic inside the mold, which begins once the plastic comes in contact with the interior mold. Slowly, as the plastic cools and starts hardening, it takes the desired shape per the mold. However, the plastic part often does shrink slightly during this cooling phase.

Later, the pellets begin to melt due to the heat around the barrel and the pressure incorporated by the machine. As per the volume of the injected material, called ‘shots,’ the injection time and process are usually complete when the shots reach 95%-99% or the mold is filled.

No one ever said that designing and manufacturing molded parts was easy. Our goal is to get you through it quickly and with quality parts. A good starting point is our Design for Moldability Toolkit.

Once you have evaluated every factor that may cost you a certain amount when using the injection molding process for a project, is that all? Probably not! It’s just as crucial to consider, understand, and evaluate how each expense takes place. The whole injection molding process may last from 2 seconds to 2 minutes. However, the limitation or extension of time for each phase involved in this process can also extend or minimize the costs.

Depending on your application's requirements, you can choose from the following when requesting an injection molding quote.

Once you understand every phase and the types of costs involved in every phase of the injection molding process, it is easier to determine the cost of plastic injection molding. As a result, with an estimated cost, you can ideally use, cater, and manage the injection molding cost to attain efficient part product outcomes.

Get machined parts anodized and chromate plated with our quick-turn finishing option. Eligible materials include aluminum 6061/6082 and 7075.

Lastly, it’s the space or area cost where the injection molding process is conducted. Again, depending on the production scale and the number of parts you need to be manufactured in the given amount of time, the space demands can differ from project to project.

Tolerances: Typically, Protolabs can maintain a machining tolerance of +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm).

For instance, if we talk about making wooden tables, electricity costs, wood costs, base and structure cost of the table, machine and equipment cost for cutting and drilling the wood, and additional décor items cost to finish the final look of the table – all of these are essential to build and complete a table that is ready to be sold and used by a potential customer.

The very first stage that should be considered for evaluating the injection mold cost for your project is clamping. The primary purpose of the clamping stage is to close both halves of the mold before the mold is injected with the material. Hence, these halves are closed with the help of a clamping unit.

It has been very enlightening to us here at HP that we are able to get parts so rapidly out of the actual materials that we're going to use in the final production.

Later, these halves are attached with an injection molding machine, where one-half is placed on the side. Once the machine starts running, the material is injected while the clamping unit consistently pushes the halves together. The machine holds these closed halves tightly together as the material is injected.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly